Welcome to our CTech Support Portal, where an exciting transition is underway. We are pleased to announce that all previously restricted but highly valuable resources are now available on www.repligen.com, without the need for login credentials.

Direct links to useful product resources

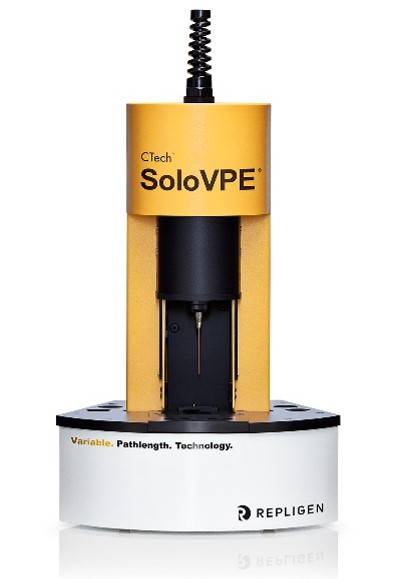

CTech™ SoloVPE® System

Avoid costly dilution with this simple, yet empowering variable pathlength solution that delivers rapid and accurate results.

CTech™ FlowVPX® System

Designed to meet the rigors of GMP requirements, the FlowVPX System offers reliable real-time results with integrated ease.

CTech™ FlowVPE® System

First generation in-line VPT system that demonstrates

the power of real-time process characterization.

Repligen Knowledge Base

Be sure to visit our Knowledge Base, a comprehensive hub designed to elevate your understanding and expertise. We strive to ensure that valuable content is readily accessible for you to stay at the forefront of your industry.

- Access extensive resources, including support documents, webinars, white papers, and application notes

- Explore the latest scientific developments through scientific posters and industry articles

- Search for what you need by product number, document number, or keyword

Helpful Videos

CTech™ Analytical Solutions Channel

Our CTech™ Analytical Solutions YouTube Channel is a comprehensive resource for all things Variable Pathlength Technology (VPT) and its applications in UV-Visible spectroscopy. With a focus on efficient analysis methods for both at-line and in-line concentration measurements, the channel offers a wealth of valuable insights and tutorials. Covering a wide array of topics, such as system operation, maintenance, troubleshooting, and software functionalities, the channel is a go-to destination for understanding SoloVPE, FlowVPE, and FlowVPX Systems. From quick checks and system suitability tests to in-depth webinars, the channel hosts a collection of informative videos aimed at enhancing your understanding and utilization of these cutting-edge analytical solutions. Visit to explore our video library.

Quality Documentation

As part of our ongoing efforts to enhance your experience, we are currently updating our Quality Document search functionality. During this period, all requests for Quality Documents will be fulfilled directly by our dedicated Repligen Support team. To obtain the documents you require, please send your request via email to

analytics-support@repligen.com or reach out to us directly by calling US +1 908-707-1201.

To ensure a swift and accurate response, kindly provide us with the specific Product (such as CHEM013, ConfiRM, Flow Cell, Flow Fibrette) along with the associated Lot Number or Serial Number. This information will help expedite the service and enable us to promptly fulfill your request.

We appreciate your understanding and patience during this transitional period.

Rest assured, our team is committed to providing you with the highest quality service and assistance.